Extrusion

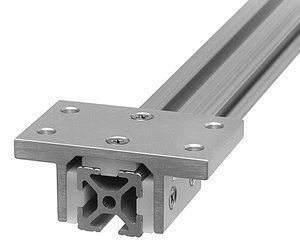

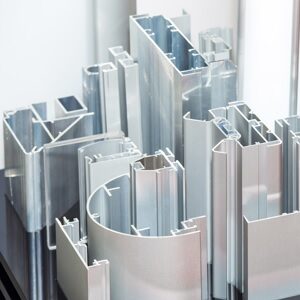

Aluminum extrusion creates parts with specific cross-sectional profiles by pushing heated alloy material through a die. Resulting in 8 to 24 foot long profiles that can then be heat treated, finished, and fabricated to customer specifications.

Our manufacturers use advanced manufacturing techniques, and the utilization of high-quality materials ensures that our aluminum extruded profiles are always of the highest standard.

Our manufacturers are equipped with advanced machinery like puller system, stretching machine with de-twisting type and cutting machine with table to adjust the length of the section as per the needs. Our advanced tool shop is capable of producing and design very intricate die setups. Our tool shop can make a wide range of precision molds to support the growing sophisticated requirement in automotive, industrial, architectural, Renewable energy, electronics, and electrical applications.

Our manufacturers use advanced manufacturing techniques, and the utilization of high-quality materials ensures that our aluminum extruded profiles are always of the highest standard.

Our manufacturers are equipped with advanced machinery like puller system, stretching machine with de-twisting type and cutting machine with table to adjust the length of the section as per the needs. Our advanced tool shop is capable of producing and design very intricate die setups. Our tool shop can make a wide range of precision molds to support the growing sophisticated requirement in automotive, industrial, architectural, Renewable energy, electronics, and electrical applications.

Material:

- Wrought Aluminium

- Aluminium Alloy

Equipment:

- Shearing machine

- Extrusion Press

- Mould heating oven

- Puller machine

- Cooling bed

- Aging furnace

Finishes:

- Mechanical Finishes

- Pre-treatment

- Bright Dipping

- Anodizing

- Liquid Paint

- Powder Coating